Empowering Precision: The Evolution of the Mini Milling and Grinding Machine

In the realm of modern manufacturing, precision and efficiency are paramount. Enter the Mini Milling and Grinding Machine, a cutting-edge tool that is redefining how small-scale milling and grinding tasks are executed. This compact yet powerful machine is gaining recognition for its remarkable ability to deliver high-quality results in a variety of applications, making it an indispensable asset for industries and hobbyists alike.

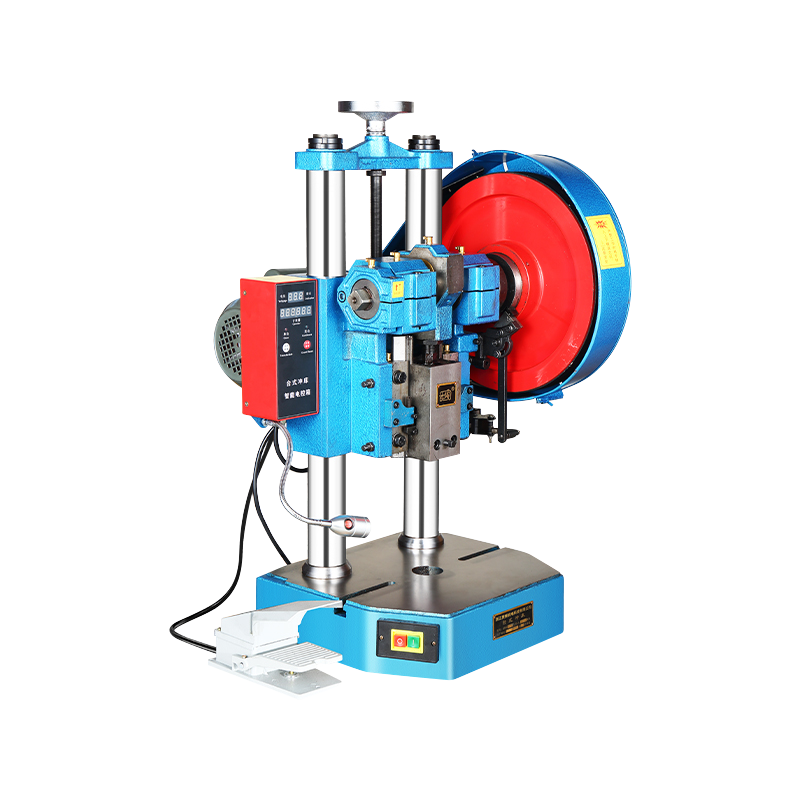

The Mini Milling and Grinding Machine represents a significant leap forward in machining technology. Designed to handle both milling and grinding operations, this versatile machine is engineered for precision and performance in a compact form. Its dual functionality allows users to switch seamlessly between milling and grinding tasks, offering flexibility and efficiency in one device.

Unlike larger, more cumbersome machines, the Mini Milling and Grinding Machine is designed for ease of use and space efficiency. Its compact size makes it suitable for small workshops, laboratories, and even home use, where space is often at a premium. Despite its small footprint, the machine boasts advanced features that ensure high performance and accuracy.

The Mini Milling and Grinding Machine is versatile and can be utilized across a range of industries. In manufacturing, it is employed for producing intricate components and parts with high precision. Its milling capability is ideal for creating detailed cuts and shapes, while its grinding function excels at refining surfaces and achieving smooth finishes.

In the realm of prototyping and research and development, the Mini Milling and Grinding Machine provides valuable support. Its ability to handle small-scale projects with precision makes it an essential tool for engineers, designers, and researchers who require accurate and reliable results in their work.

For hobbyists and DIY enthusiasts, this machine offers a way to bring creative projects to life. Whether it’s crafting custom parts, working on model building, or performing detailed repairs, the Mini Milling and Grinding Machine provides the necessary functionality to achieve professional-quality results in a compact, user-friendly package.

The economic benefits of the Mini Milling and Grinding Machine are substantial. Its dual functionality eliminates the need for multiple machines, saving on both equipment costs and space. This cost-effectiveness is particularly advantageous for small businesses and individuals who need versatile tools without the investment required for larger machines.

Operationally, the Mini Milling and Grinding Machine enhances productivity and precision. Its advanced controls and features enable users to perform tasks with minimal setup and adjustment time. This efficiency translates into faster production cycles and reduced labor costs, contributing to improved overall productivity.

Additionally, the machine’s ease of use and minimal maintenance requirements make it an attractive option for users at all skill levels. With straightforward operation and reliable performance, users can achieve consistent results with less effort and fewer complications.

Recent advancements in the Mini Milling and Grinding Machine have introduced several innovative features that enhance its capabilities. Modern models are equipped with advanced control systems that allow for precise adjustments of milling and grinding parameters, such as speed and depth. These controls provide users with greater flexibility and accuracy in their work.

The integration of high-quality materials and components has also improved the durability and reliability of the machine. Newer models are designed to withstand rigorous use and offer long-lasting performance, ensuring that users get the value from their investment.

Safety features have become increasingly important in the latest Mini Milling and Grinding Machines. These machines are now equipped with protective mechanisms and safety controls that safeguard users from potential hazards, contributing to a safer working environment.

The market for Mini Milling and Grinding Machines is expanding as industries and individuals alike recognize the value of compact, versatile machining solutions. The demand for these machines is driven by the need for precision, efficiency, and cost-effectiveness in a variety of applications.

-

Feedback

English

English 中文简体

中文简体