Foot Operated Electric Punch Press: Redefining Efficiency in Precision Manufacturing

The advent of the Foot Operated Electric Punch Press marks a significant advancement in the realm of precision manufacturing. This innovative machine combines the simplicity of manual operation with the power of electric assistance, offering unparalleled efficiency and accuracy. Its introduction is set to revolutionize various industries, from metalworking to textiles, where precision and speed are paramount.

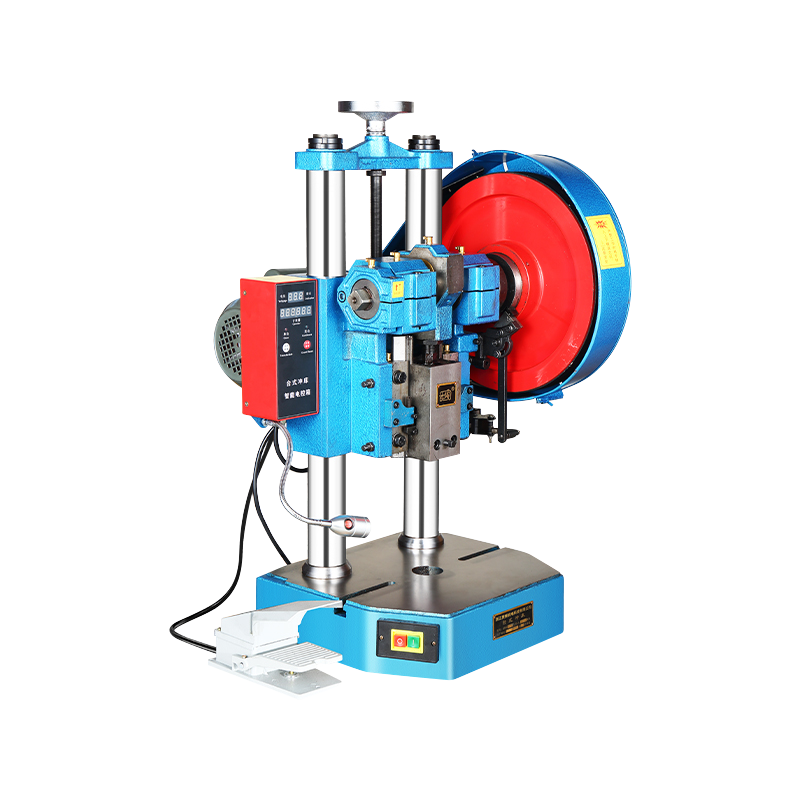

The Foot Operated Electric Punch Press stands out with its ergonomic design and user-friendly features. Unlike traditional punch presses that require manual hand operation, this press is activated using a foot pedal, which allows for hands-free operation. This design not only reduces operator fatigue but also enhances precision, as the hands are free to position materials accurately under the punch.

The electric component of the machine provides consistent punching force, which is crucial for achieving uniform results across large production runs. This consistency is particularly beneficial in industries where exact specifications are critical, such as in the production of electronic components, jewelry, and custom metalwork.

One of the key benefits of the Foot Operated Electric Punch Press is its efficiency. The foot pedal mechanism enables rapid punching, significantly speeding up production times compared to manual presses. This increased speed does not come at the cost of precision; the electric motor ensures that each punch is delivered with consistent force, reducing the likelihood of errors and material waste.

The machine's precision is further enhanced by adjustable settings that allow operators to control the punching force and depth. This level of customization makes the Foot Operated Electric Punch Press versatile, capable of handling a wide range of materials and thicknesses. Whether working with delicate fabrics or robust metals, operators can achieve clean, accurate cuts every time.

Ergonomics play a crucial role in the design of the Foot Operated Electric Punch Press. The foot pedal operation reduces the strain on the upper body, which is common with hand-operated presses. This feature is especially valuable in high-volume production environments, where operators may use the machine for extended periods.

The machine's design also includes safety features, such as guards and sensors, to protect operators from accidental injuries. These features make the press suitable for educational settings and smaller workshops, where safety is a primary concern.

The Foot Operated Electric Punch Press offers several environmental and economic advantages. Its electric operation is energy-efficient, consuming less power than larger, fully automated systems. This efficiency translates to lower operating costs, making it an economical choice for small businesses and workshops.

Additionally, the machine's ability to produce precise cuts with minimal waste contributes to resource conservation. This is an important consideration in industries focused on sustainability, as reducing waste not only lowers costs but also minimizes environmental impact.

The versatility of the Foot Operated Electric Punch Press makes it applicable across a broad range of industries. In the metalworking sector, it is used for tasks such as punching holes, shaping metal parts, and creating intricate designs. The precision offered by the press is crucial for producing components that meet exact specifications, which is essential in industries like automotive manufacturing and aerospace.

In the textile and leather industries, the press is used to cut patterns and shapes, streamlining the production of garments, accessories, and other goods. Its ability to handle a variety of materials without compromising on quality makes it a valuable tool for artisans and small-scale manufacturers.

The future of the Foot Operated Electric Punch Press looks promising, with ongoing innovations aimed at enhancing its capabilities. Future models may feature more advanced automation options, improved ergonomic designs, and even greater energy efficiency. These advancements will further cement the machine's role as a critical tool in precision manufacturing.

As industries continue to evolve, the demand for tools that offer both efficiency and precision will grow. The Foot Operated Electric Punch Press, with its unique blend of manual and electric features, is well-positioned to meet this demand. Its adoption across various sectors will likely expand, driven by the need for high-quality, reliable, and cost-effective production solutions.

-

Feedback

English

English 中文简体

中文简体