How Asynchronous Engines Work And Why They Matter?

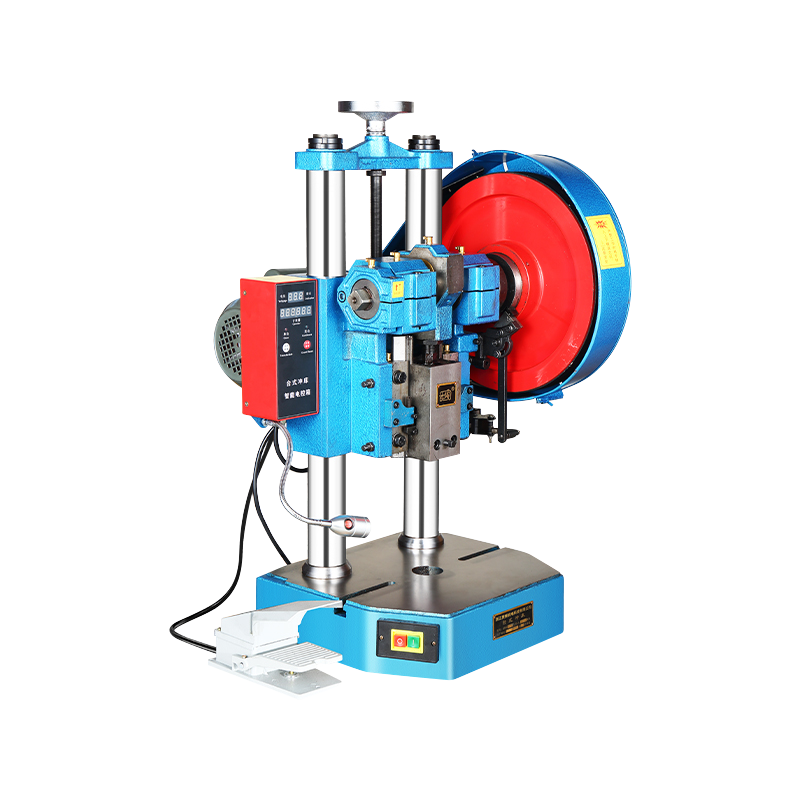

Sale Cheap Asynchronous Vectorial Engine Motors Manufacturers

In the intricate world of mechanical engineering, the term "asynchronous engine" refers to a type of engine that operates on a principle distinct from that of a synchronous engine. Understanding how it works is crucial for anyone involved in the design, operation, or maintenance of machinery that relies on these powerful devices. This article will explore the inner workings of Sale asynchronous engines, their unique characteristics, and the reasons why they matter in various industrial and technological applications.

An asynchronous engine, also known as an induction motor, is a type of AC motor in which the rotor rotates at a speed less than the synchronous speed of the stator's magnetic field. This difference in speed is what gives one its name. The operation of an one is based on the principle of electromagnetic induction, which was discovered by Michael Faraday in 1831. When an alternating current (AC) is passed through the stator windings, it creates a rotating magnetic field. This field induces a current in the rotor, which in turn creates a magnetic field of its own. The interaction between these two fields results in a torque that causes the rotor to turn.

The asynchronous engine has several key components that contribute to its operation. The stator is the stationary part of the motor, which houses the windings through which the AC current is passed. The rotor, on the other hand, is the rotating part that is driven by the induced current. In some designs, the rotor may have windings and slip rings, while in others, it may be a simpler squirrel-cage design with bars and end rings. The air gap between the stator and rotor is another critical component, as it allows the magnetic fields to interact without physical contact.

One of the primary benefits of Cheap Asynchronous Vectorial Motors is their simplicity and robustness. They do not require complex starting mechanisms like those found in synchronous engines, which means they are less prone to failure and easier to maintain. This makes them an attractive option for applications where reliability is paramount, such as in industrial machinery, HVAC systems, and electric vehicles.

Another advantage of asynchronous engines is their ability to operate over a wide range of speeds. This is due to the variable speed of the rotor relative to the stator's magnetic field. This characteristic allows for smooth and efficient operation, even under fluctuating load conditions. In contrast, synchronous engines are designed to operate at a fixed speed, which can limit their flexibility in certain applications.

Asynchronous engines also offer efficiency, particularly when compared to their direct current (DC) counterparts. The use of AC current reduces energy losses and allows for more efficient power transfer. This efficiency is further enhanced by the fact that it can be designed to operate at or near its ideal efficiency point, which is not always the case with other types of engines.

In addition to their operational benefits, asynchronous engines also have a significant impact on energy consumption and sustainability. Their high efficiency means that they consume less power to perform the same work as other types of engines, which can result in significant energy savings over time. This is particularly important in today's world, where there is a growing emphasis on reducing energy consumption and reducing the environmental impact of our technological infrastructure.

Despite their many advantages, Asynchronous Motor Manufacturers do have some limitations. For example, they are not well-suited for applications that require precise speed control, as their speed can vary depending on the load. Additionally, the starting torque of one is typically lower than that of a synchronous engine, which can be a disadvantage in applications that require high starting torque.

In conclusion, asynchronous engines play a vital role in a wide range of industrial and technological applications due to their simplicity, robustness, efficiency, and adaptability. Understanding how these engines work and the benefits they offer is essential for anyone involved in the design, operation, or maintenance of machinery that relies on them. As technology continues to advance, it is likely that the role of asynchronous engines will only become more significant, as we strive to create more efficient and sustainable systems for the future.

-

Feedback

English

English 中文简体

中文简体