Innovation in Precision: The Small Desktop Two-hand Button Electric Press Machine

In the evolving landscape of manufacturing technology, the Small Desktop Two-hand Button Electric Press Machine is making a significant impact on small-scale production and precision engineering. This cutting-edge device combines the precision of electric machinery with user-friendly controls, setting new benchmarks for efficiency and safety in compact work environments. As industries seek more versatile and space-efficient solutions, the Small Desktop Two-hand Button Electric Press Machine emerges as a key player in transforming production workflows.

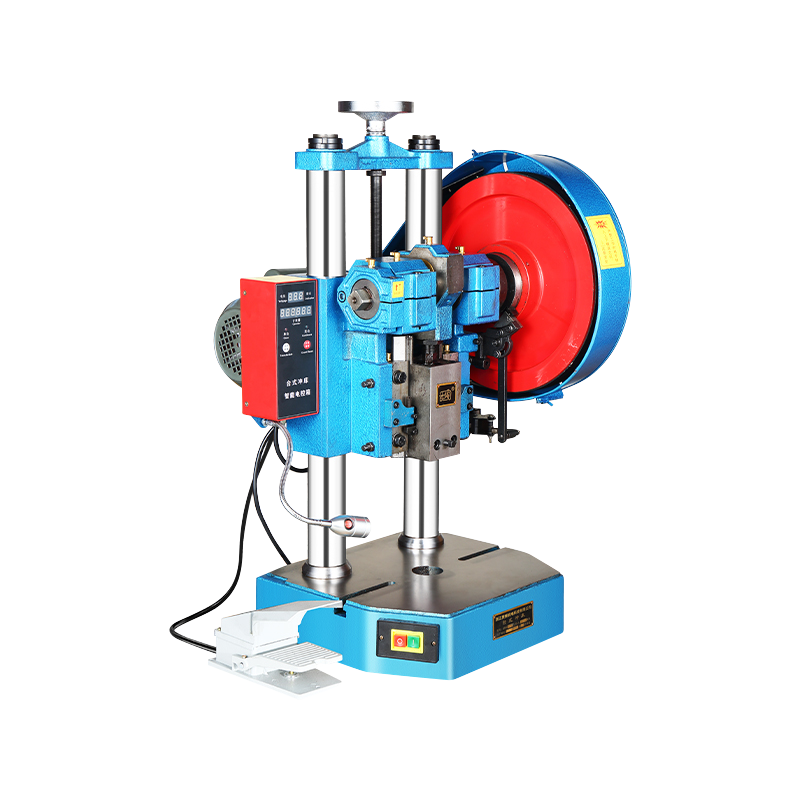

The Small Desktop Two-hand Button Electric Press Machine is engineered to offer precise and reliable performance in a compact form factor. Unlike larger, bulkier press machines, this model is designed to fit seamlessly into smaller workspaces, making it ideal for workshops, laboratories, and small-scale production environments. Its two-hand button operation ensures that users can operate the machine safely and efficiently, minimizing the risk of accidents and enhancing overall productivity.

The machine's design features a robust electric motor that powers the pressing mechanism with consistent force. The two-hand button control system is a significant safety feature, requiring operators to use both hands to activate the machine, thus preventing accidental activation and ensuring that hands are clear from the press area during operation.

The Small Desktop Two-hand Button Electric Press Machine excels in various applications across different industries. In the electronics sector, it is used for pressing and assembling small electronic components with high precision. The machine's ability to deliver consistent pressure makes it ideal for tasks such as stamping circuit boards or assembling electronic housings.

In the medical and laboratory fields, the machine is employed for tasks such as pressing and testing samples. Its precise control allows for accurate and repeatable results, which are crucial in scientific research and quality control processes. The machine’s compact size also allows it to fit into tight laboratory spaces, making it a practical choice for specialized applications.

The Small Desktop Two-hand Button Electric Press Machine is also gaining popularity in the craft and jewelry-making industries. Artisans and jewelers use it for tasks such as embossing, stamping, and shaping materials. Its precise control and manageable size make it an tool for creating detailed and intricate designs.

One of the primary advantages of the Small Desktop Two-hand Button Electric Press Machine is its cost-effectiveness. Compared to larger, industrial press machines, this model is more affordable, making it accessible to small businesses, hobbyists, and educational institutions. Its lower initial investment and reduced operational costs make it an attractive option for users seeking precision without significant financial outlay.

Operational efficiency is another key benefit. The machine's two-hand button control system simplifies the pressing process and reduces the likelihood of operator errors. The electric motor provides consistent and reliable performance, which enhances productivity and ensures that each pressing task is completed with high accuracy.

The compact design of the Small Desktop Two-hand Button Electric Press Machine is also advantageous for users with limited workspace. Its small footprint allows it to be positioned on desktops or workbenches, optimizing space utilization and making it easy to store when not in use.

Recent advancements in the Small Desktop Two-hand Button Electric Press Machine have introduced several innovative features that enhance its performance and usability. Modern models often include digital displays and adjustable settings, allowing operators to customize the pressing parameters according to specific needs.

Some machines are equipped with interchangeable dies, enabling users to switch between different sizes and shapes of pressing tools with ease. This versatility expands the range of applications and allows for greater customization based on project requirements.

Ergonomic improvements in the design, such as adjustable worktables and comfortable button placements, contribute to a more user-friendly experience. These features help reduce operator fatigue and improve overall efficiency during extended use.

-

Feedback

English

English 中文简体

中文简体