Innovations in Manual Punch Press Machines

Custom OEM Manual Portable Punch Press Machine Manufacturers

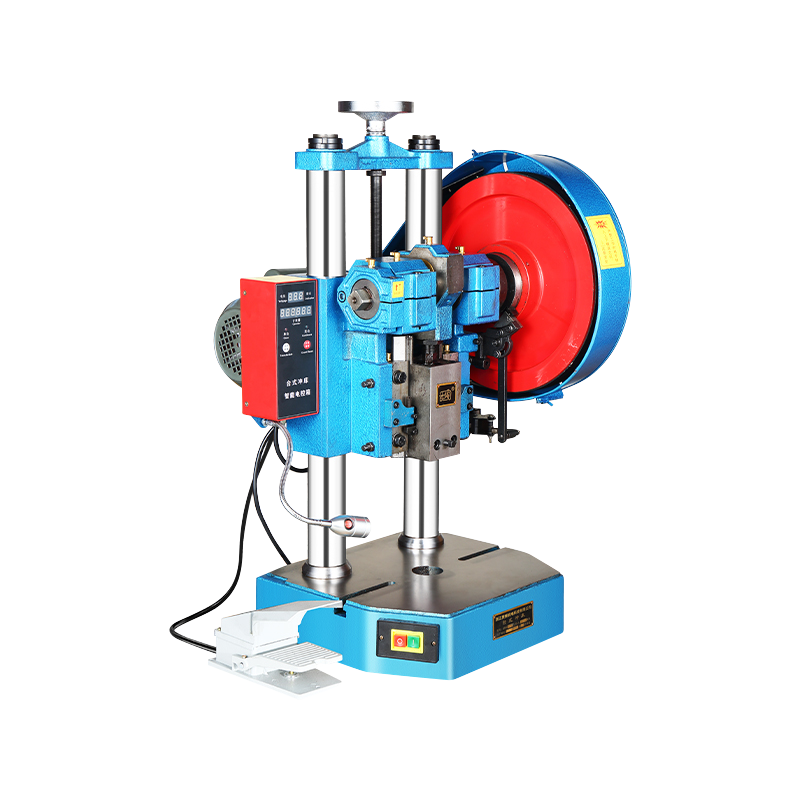

The Manual Punch Press Machine, a stalwart in the manufacturing industry, has seen a surge of innovation in recent years. These machines, once simple in design, have evolved to meet the demands of modern production with precision, versatility, and user-friendliness at the forefront of their development. This article delves into the advancements in Custom Manual Punch Press Machine technology and how they are shaping the future of metalworking.

The Manual Punch Press Machine is a mechanical device used for punching holes in metal sheets, typically in a factory setting. It is an essential tool for various industries, including automotive, aerospace, and electronics, where precision and repeatability are paramount. Traditionally, these machines have been operated manually, requiring the operator to physically control the press's movement and pressure. However, recent innovations have transformed the Manual Punch Press Machine into a more sophisticated and efficient piece of equipment.

The Manual Punch Press Machine has come a long way from its early days. Early models were rudimentary, with limited capabilities and a high reliance on operator skills. Over time, improvements in materials, design, and engineering have led to machines that are more robust, accurate, and easier to use. The Manual Punch Press Machines incorporate advanced features such as programmable controls, digital readouts, and safety interlocks, making them more reliable and user-friendly.

One of the significant innovations in Manual Punch Press Machines is the improvement in precision and accuracy. Modern machines feature high-precision components, such as hardened steel dies and precision-ground rams, which ensure that each punch is made with exacting accuracy. Additionally, some machines now come with digital readouts that allow operators to make fine adjustments to the punch position, further enhancing the accuracy of the process.

The ergonomic design of Manual Punch Press Machines has also seen significant advancements. Newer models are designed with the operator's comfort and safety in mind, featuring adjustable controls, better visibility, and improved access to the work area. Safety features such as emergency stop buttons, safety guards, and interlocking mechanisms have also been incorporated to reduce the risk of accidents and injuries.

Innovations in material handling have also been crucial for the OEM Punch Press Manufacturers. Modern machines often come with features such as automatic sheet feeders and stackers, which streamline the process of loading and unloading materials. This not only saves time but also reduces the physical strain on operators.

As the world moves towards more sustainable practices, energy efficiency has become a key consideration in the design of Manual Punch Press Machines. Newer models are designed to consume less energy during operation, with features such as energy-saving motors and optimized hydraulic systems. This not only reduces operational costs but also aligns with environmental sustainability goals.

The durability and ease of maintenance of Manual Punch Press Machines have also seen improvements. Modern machines are built with high-quality materials and components that are designed to withstand the rigors of daily use. Additionally, many machines now feature modular designs, making it easier to replace parts and perform maintenance.

As technology continues to advance, the Manual Punch Press Machine is expected to evolve further. Future innovations may include the integration of artificial intelligence for predictive maintenance, the use of advanced materials for lighter and stronger machines, and the development of more sophisticated automation systems.

The Portable Punch Press has come a long way since its inception, and the innovations discussed in this article are a testament to the ongoing commitment to improving this essential piece of equipment. As manufacturers continue to push the boundaries of what is possible, the Manual Punch Press Machine will remain a critical tool in the pursuit of precision, efficiency, and innovation in the world of metalworking.

-

Feedback

English

English 中文简体

中文简体