Maintenance And Maintenance Of The Manual Punch Press Machine

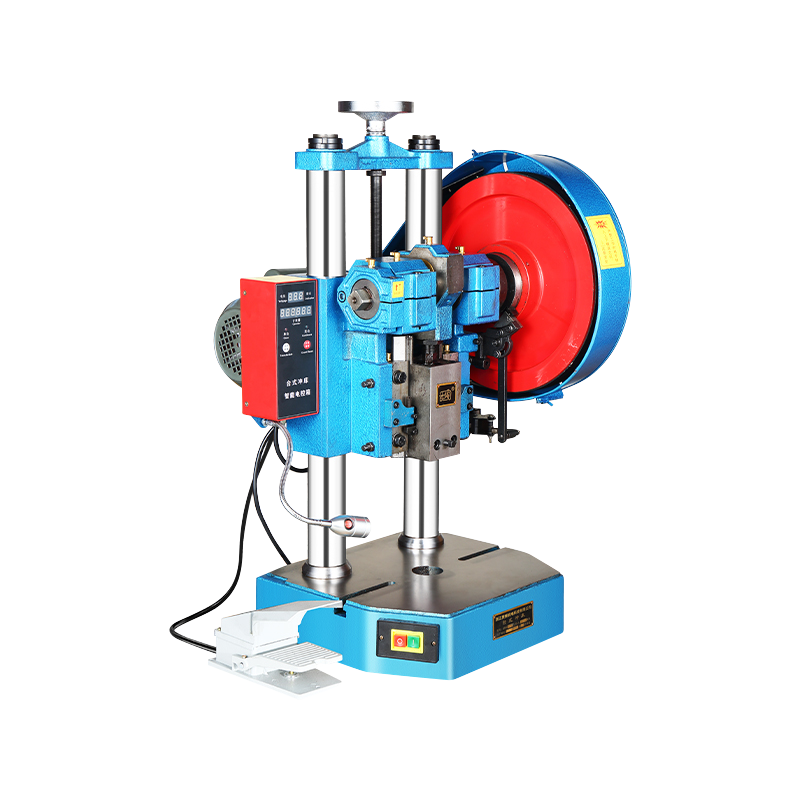

Sale OEM Manual Single Station Mechanical Punch Press Machine Maker

The Manual Punch Press Machine is a critical piece of equipment in many manufacturing and fabrication environments. Its ability to perform precise punching operations on a variety of materials is unparalleled, making it a valuable asset in any workshop. However, like any machinery, the Sale Manual Punch Press Machine requires regular maintenance to ensure its longevity, efficiency, and safety. This article will delve into the importance of maintenance for the Manual Punch Press Machine, the steps involved, and the benefits of a well-maintained system.

Regular maintenance is essential for the Manual Punch Press Machine to function ideally. By addressing wear and tear, the life of the machine can be significantly extended. A well-maintained machine is less likely to cause accidents due to mechanical failure. A machine that is regularly serviced will operate more efficiently, reducing downtime and increasing productivity. Preventative maintenance can be more cost-effective than dealing with major repairs after a breakdown.

To keep the Manual Punch Press Machine in better condition, the following routine maintenance checks should be performed. Regularly inspect the machine for any visible signs of damage or wear. Ensure that all moving parts are well-lubricated to reduce friction and prevent overheating. Keep the machine clean, removing any debris or metal shavings that could cause damage. Check all bolts and screws for tightness to prevent loosening over time. Test the machine's operation to ensure it is performing as expected.

Beyond routine checks, advanced maintenance may be required to address specific issues or to perform more in-depth servicing. Over time, parts such as dies, punches, and bearings may wear out and need replacement. The machine may need to be calibrated to ensure accuracy in punching operations. If the Manual Punch Press Machine has electrical components, these should be inspected for any signs of damage or malfunction. For hydraulic models, the hydraulic system should be checked for leaks and proper fluid levels.

While some maintenance tasks can be performed by in-house staff, others may require the expertise of professional maintenance services. A thorough examination of the Manual Punch Press Machine to identify any potential issues. Access to specialized tools and knowledge to perform complex repairs. Assistance in training staff on proper maintenance procedures for the Manual Punch Press Machine.

Neglecting maintenance can have serious consequences for the Manual Punch Press Machine, including Unmaintained machines being more likely to break down, resulting in costly downtime. A machine that is not operating efficiently can slow down production. A poorly maintained machine can pose a risk to operators and the surrounding environment. The cost of repairing a machine that has been neglected can be significantly higher than the cost of regular maintenance.

To get the out of your OEM Single Station Punch Press, follow these practices. Establish a regular maintenance schedule and stick to it. When replacing parts, use high-quality components to ensure the machine's performance. Maintain records of all maintenance activities to track the machine's condition over time. Ensure that all staff who operate the Manual Punch Press Machine are properly trained in its maintenance.

The Mechanical Punch Press Maker is a powerful tool that, when properly maintained, can significantly enhance the capabilities of any workshop. By following a regular maintenance schedule and investing in the necessary resources, businesses can ensure that their Manual Punch Press Machine remains a reliable and efficient part of their production process. Remember, the key to a long-lasting and productive Manual Punch Press Machine lies in its upkeep.

-

Feedback

English

English 中文简体

中文简体