Manual Punch Press vs. CNC Punch Press: Which Is Better for Your Workshop?

When it comes to sheet metal fabrication and other punching tasks in a workshop, two common types of punch presses are often considered: the manual punch press and the CNC punch press. Both have their own distinct advantages and disadvantages depending on the specific requirements of the job. Choosing the right punch press for your workshop involves understanding the differences between the two, as well as how each one aligns with the nature of your production. In this article, we will compare the China manual punch press and the CNC punch press, helping you determine which one is more suitable for your manufacturing needs.

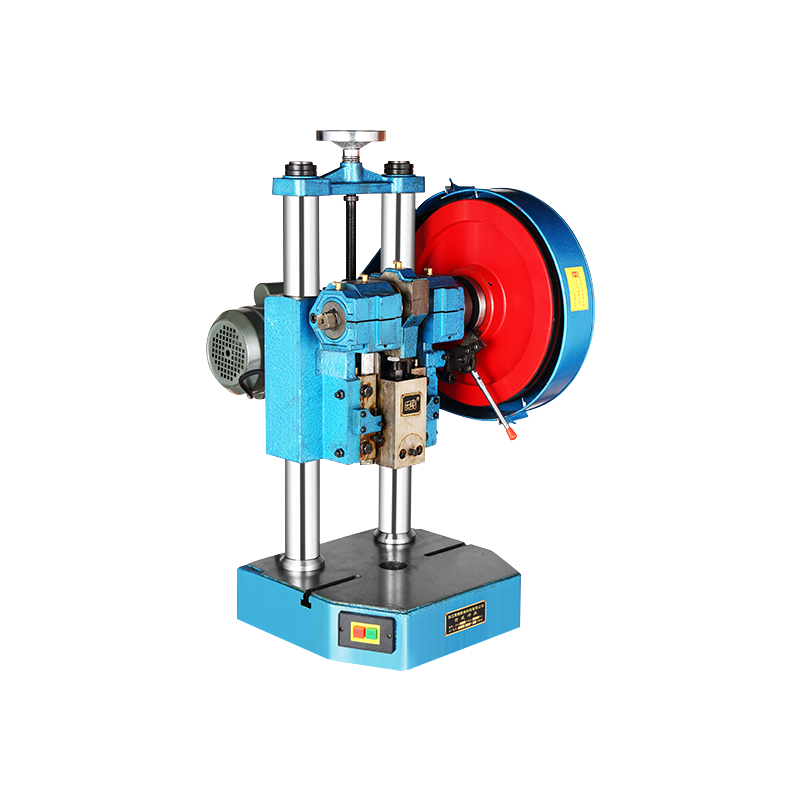

A manual punch press is a mechanical device that requires the operator to apply force by hand to punch holes or shapes into materials such as metal, plastic, or wood. The operator typically uses a lever or foot pedal to engage the machine, providing control over the punching action. Punch presses are typically simpler in design and can handle various tasks, including punching, notching, and blanking. These machines are ideal for small production runs, prototypes, or situations where precision is important but automation isn’t necessary.

One of the significant factors that differentiate a manual punch press from a CNC punch press is the cost. A punch press is generally much more affordable, both in terms of initial purchase price and ongoing maintenance costs. For smaller businesses or workshops with limited budgets, the punch press presents a cost-effective solution. It does not require the expensive software, training, and setup time associated with a CNC punch press.

Additionally, the maintenance and repair costs of a CNC punch press can be higher, as it is more complex and may require specialized technicians to keep it running smoothly. For small-scale workshops or those with low production volumes, the manual punch press may be a better choice in terms of overall cost-effectiveness.

While both types of presses offer precision, the level of accuracy varies. A Wholesale Metal Hole Punch Press allows for a high degree of precision, but the operator's skill and experience play a significant role in achieving the desired results. While many experienced workers can produce very accurate results with a punch press, it still relies on the operator's judgment and consistency.

A CNC punch press, however, provides a higher level of consistency and precision, especially when working with complex shapes or high volumes. The computer-controlled nature of the CNC machine ensures that each punch is executed exactly the same way, eliminating human error. If your workshop requires high precision for intricate designs, a CNC punch press may be the better option.

In terms of speed, a manual punch press is generally slower than a CNC punch press. While a skilled operator can work quickly with a manual punch press, the process still requires more hands-on involvement, and the operator can only punch a single hole or shape at a time. This can be limiting for high-volume production, where speed and efficiency are essential.

On the other hand, a CNC punch press can perform multiple operations automatically in a short period, greatly increasing the speed of production. Once the machine is programmed, it can operate without the need for constant supervision, allowing for continuous production. If your workshop requires fast turnaround times and high-volume production, the CNC punch press is likely the better choice for efficiency.

Both the manual punch press and the CNC punch press offer flexibility but in different ways. A punch press is versatile in terms of handling various materials and small production runs. Its straightforward design allows for quick adjustments, making it a great tool for custom or prototype work where flexibility is important.

Operating a Portable Punch Press Factory requires skilled labor. The operator must be familiar with the specific requirements of the task at hand and be able to adjust the machine manually to achieve the desired results. While the learning curve may be shorter for a manual punch press, the machine still demands consistent attention and expertise from the operator.

In conclusion, the choice between a manual punch press and a CNC punch press depends largely on the specific needs of your workshop. If your operation requires low-volume production, customization, or a lower initial investment, the punch press is a solid option. It offers control, reliability, and flexibility without the complexity and cost associated with CNC machines.

-

Feedback

English

English 中文简体

中文简体