Revolutionizing Precision: The Impact of Portable Semi-Automatic Tapping Machine

In the world of manufacturing and industrial operations, the Portable Semi-Automatic Tapping Machine has emerged as a game-changer, providing unparalleled precision and efficiency. This innovative tool is transforming how tapping operations are performed across various sectors, offering both flexibility and enhanced performance. As industries continue to seek ways to improve productivity and reduce operational costs, the Portable Semi-Automatic Tapping Machine stands out as a vital solution.

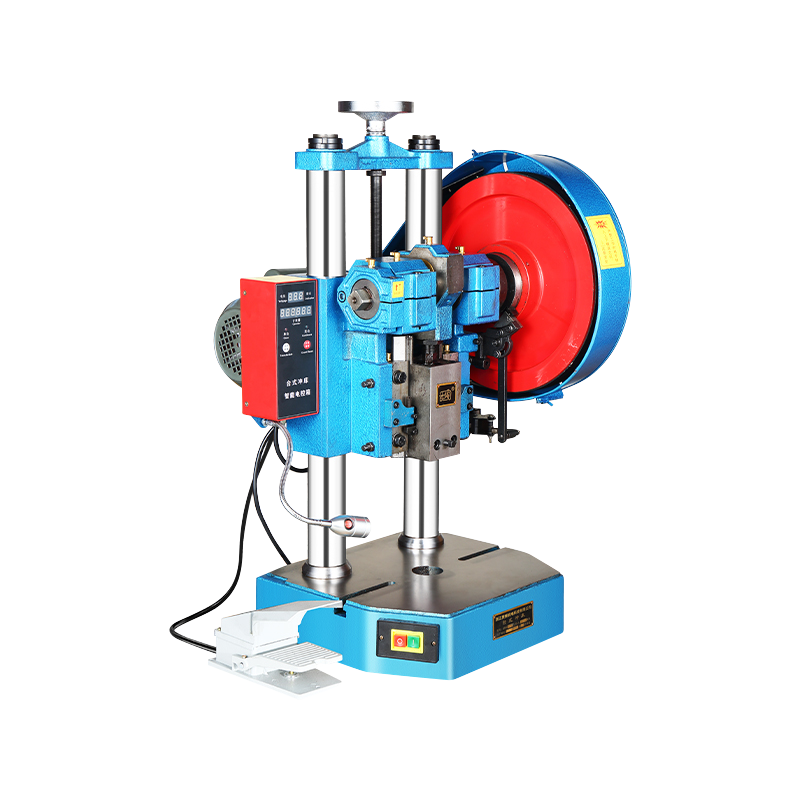

The Portable Semi-Automatic Tapping Machine represents a significant advancement in tapping technology. Unlike traditional tapping methods, which often involve manual handling and labor-intensive processes, this machine combines the benefits of automation with portability. Designed for ease of use and adaptability, the Portable Semi-Automatic Tapping Machine is engineered to streamline the tapping process, making it a valuable asset in both workshop and field environments.

This machine operates with a semi-automatic system, which means it requires minimal manual intervention while still providing the precision and control necessary for high-quality tapping. The portability aspect allows for its use in various locations, enhancing its versatility and practicality in different industrial settings.

The Portable Semi-Automatic Tapping Machine is versatile and applicable in numerous industries, including automotive, aerospace, electronics, and general manufacturing. Its primary function is to create precise threads in materials such as metal, plastic, and composites, which is essential for assembling components and machinery.

One of the key benefits of the Portable Semi-Automatic Tapping Machine is its ability to improve operational efficiency. Traditional tapping methods can be time-consuming and labor-intensive, often requiring multiple setups and adjustments. The semi-automatic feature of this machine reduces setup times and minimizes the need for manual intervention, to faster production cycles and increased throughput.

Additionally, the machine's portability offers significant advantages. Operators can easily move it to different workstations or job sites, making it ideal for on-site applications where space and equipment may be limited. This flexibility is particularly valuable in industries where components need to be tapped in various locations or in field operations where mobility is crucial.

The economic benefits of the Portable Semi-Automatic Tapping Machine are substantial. By reducing manual labor and increasing productivity, the machine helps lower labor costs and operational expenses. Its efficiency in performing tapping operations translates to higher production rates and less downtime, which contributes to improved profitability.

Operationally, the Portable Semi-Automatic Tapping Machine enhances precision and consistency. Traditional tapping methods can result in variations in thread quality and alignment, to potential issues with component fitting and functionality. The semi-automatic system ensures consistent results with each operation, reducing the likelihood of defects and the need for rework.

Moreover, the machine's user-friendly design simplifies its operation, requiring minimal training for new operators. This ease of use further enhances its cost-effectiveness, as it minimizes the learning curve and allows for quicker integration into existing workflows.

Recent advancements in the design and functionality of the Portable Semi-Automatic Tapping Machine have introduced several innovative features. Modern versions of this machine are equipped with advanced control systems that allow for precise adjustment of tapping parameters, such as depth and speed. These controls enable operators to tailor the machine's performance to specific requirements, enhancing versatility and accuracy.

Enhanced durability and construction are also notable improvements. The latest models are built with high-quality materials and components that withstand rigorous use and challenging environments. This robustness ensures reliable performance and a longer service life, reducing the need for frequent maintenance or replacement.

Additionally, some models feature integrated safety mechanisms that protect operators from potential hazards. These safety features contribute to a safer working environment and comply with industry standards and regulations.

The market for Portable Semi-Automatic Tapping Machines is growing as industries increasingly recognize the advantages of automation and portability. The demand for these machines is driven by the need for higher precision, faster production cycles, and reduced labor costs.

-

Feedback

English

English 中文简体

中文简体