The Role of Manual Punch Press Machines in Manufacturing

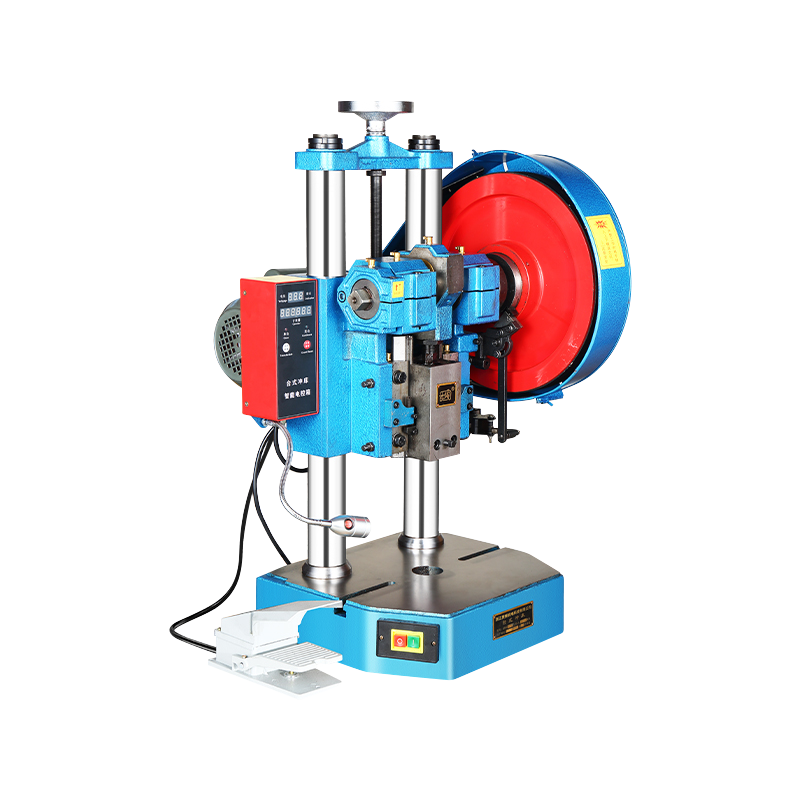

China Sale Manual Punch Press Machine Supplier

In the world of manufacturing, precision and efficiency are paramount. One of the key tools that have stood the test of time in this industry is the manual punch press machine. This versatile piece of equipment plays a significant role in various manufacturing processes, from automotive to electronics and beyond. China Manual Punch Press Machine, despite its simplicity, offers a level of control and customization that is unmatched by its automated counterparts.

The manual punch press machine has a rich history, dating back to the early days of the Industrial Revolution. It was a significant leap forward from the hand tools that preceded it, allowing for greater accuracy and speed in punching holes and cutting shapes in metal sheets. Over the years, the design and functionality have evolved, but its core purpose remains the same: to provide a reliable and precise method for shaping materials.

The manual punch press machine operates on a simple yet effective principle. It uses a lever system to amplify the force applied by the operator, allowing for the punching of holes or cutting of materials with little effort. The operator manually positions the punch and die, ensuring that the material is correctly aligned before applying pressure. This manual control allows for adjustments to be made on the fly, accommodating variations in material thickness or the need for custom shapes.

One of the primary advantages of the manual punch press machine is its precision. The operator has complete control over the depth and location of the punch, which is crucial for high-quality manufacturing. This level of control is particularly important in industries where tolerances are tight, such as aerospace or medical device manufacturing. Additionally, it can be easily adapted to create custom shapes and sizes, making it an invaluable tool for prototyping and small-batch production.

For small to medium-sized businesses, the manual punch press machine offers a cost-effective solution for punching and cutting operations. Unlike automated or CNC punch press machines, which can be expensive to purchase and maintain, the manual punch press machine requires less capital investment. This makes it an attractive option for businesses that need to keep overhead costs low while still maintaining a high level of production quality.

While the Sale Manual Punch Press offers many benefits, it is essential to consider safety when operating this equipment. Operators must be trained in the proper use of the machine, including how to handle the punch and die, and how to secure the material being worked on. Regular maintenance and inspection of the manual punch press machine are also crucial to ensure that it operates safely and efficiently.

The manual punch press machine is used in a wide range of manufacturing applications. In the automotive industry, it is used to punch holes in metal sheets for the assembly of car bodies and components. In electronics manufacturing, it is employed to create precise openings in metal casings for wiring and components. It is also commonly used in the production of metal furniture, where it can be used to create decorative patterns or functional features.

A well-maintained manual punch press machine can last for many years, providing reliable service in a manufacturing environment. Regular cleaning, lubrication, and inspection of the machine's components are essential to ensure its longevity. The durability of it is one of its key selling points, as it can withstand the rigors of daily use without the need for frequent replacement.

Despite the rise of automation and advanced manufacturing technologies, the Punch Press Manual Supplier continues to hold its own in the industry. Its versatility, precision, and cost-effectiveness make it a valuable asset for many manufacturers. As technology continues to evolve, it is likely that the manual punch press machine will be integrated with new systems and tools, enhancing its capabilities and ensuring its continued relevance in the manufacturing landscape.

In conclusion, the manual punch press machine plays a vital role in the manufacturing industry. Its ability to provide precise and customized punching and cutting operations, coupled with its cost-effectiveness and durability, make it an indispensable tool for many businesses. As manufacturers continue to seek ways to improve efficiency and quality, it will remain a key player in the production process.

-

Feedback

English

English 中文简体

中文简体