Elevating Precision with the Heavy-Duty Bench Electric Burnishing Polishing Machine

In the realm of industrial finishing and surface treatment, the Heavy-Duty Bench Electric Burnishing Polishing Machine is setting new standards for precision and efficiency. This robust tool is designed to enhance the quality of polished surfaces across various industries, offering exceptional performance and durability. As manufacturers and craftsmen seek to achieve finishes, the Heavy-Duty Bench Electric Burnishing Polishing Machine is proving to be an indispensable asset.

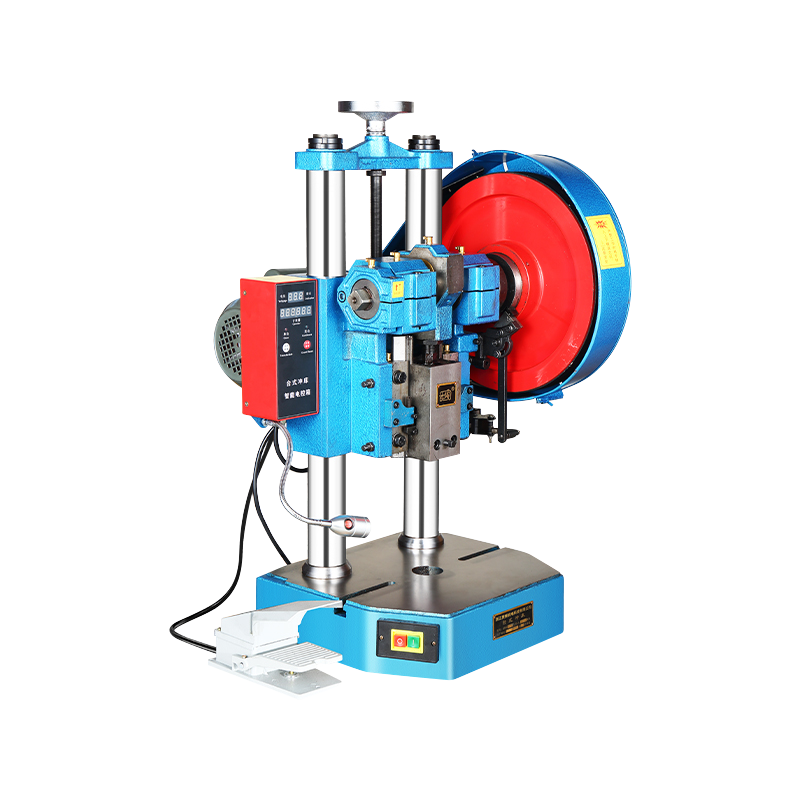

The Heavy-Duty Bench Electric Burnishing Polishing Machine is engineered to deliver high-quality surface finishes on a range of materials, including metals, plastics, and composites. Unlike traditional polishing methods, this machine integrates advanced electric technology with a heavy-duty build to provide consistent and efficient results. The machine's design focuses on durability, making it ideal for both heavy industrial applications and smaller-scale workshops.

At its core, the Heavy-Duty Bench Electric Burnishing Polishing Machine uses powerful electric motors to drive its polishing and burnishing tools. This electric drive system ensures a steady and controlled polishing process, which is crucial for achieving the desired surface quality. The machine’s heavy-duty construction allows it to handle demanding tasks, making it suitable for use in environments where durability and reliability are paramount.

The Heavy-Duty Bench Electric Burnishing Polishing Machine is versatile and can be applied in various industries. In metalworking, it is used to polish and burnish metal parts, removing imperfections and achieving a smooth, reflective finish. This is essential for components in aerospace, automotive, and machinery applications where high-quality surface finishes are required.

In the manufacturing of consumer products, such as jewelry and decorative items, the machine enhances the aesthetic appeal of the finished products. Its ability to deliver a high-quality polish makes it an invaluable tool for achieving a professional look and feel.

The machine’s effectiveness extends to plastic and composite materials as well. By using appropriate polishing wheels and compounds, it can achieve a high gloss finish on a variety of non-metal surfaces, making it suitable for applications in the electronics and automotive industries.

One of the significant advantages of the Heavy-Duty Bench Electric Burnishing Polishing Machine is its efficiency. The machine's electric drive system provides consistent power, which translates to faster processing times and increased productivity. This efficiency helps reduce labor costs and enhances overall operational throughput.

From an operational perspective, the Heavy-Duty Bench Electric Burnishing Polishing Machine offers ease of use and minimal maintenance. Its robust construction is designed to withstand the rigors of heavy use, reducing the need for frequent repairs and downtime. The machine’s user-friendly controls and adjustable settings allow operators to customize the polishing process according to specific requirements, further enhancing its versatility and efficiency.

Additionally, the machine's precision and consistency in delivering high-quality finishes contribute to improved product quality. By achieving uniform surface finishes, manufacturers can ensure that their products meet stringent quality standards and reduce the likelihood of defects or rework.

Recent advancements in the Heavy-Duty Bench Electric Burnishing Polishing Machine have introduced several features that enhance its performance and usability. Modern models are equipped with variable speed controls, allowing operators to adjust the polishing speed according to the material and desired finish. This flexibility is crucial for handling different types of workpieces and achieving results.

Some machines now come with advanced cooling systems that prevent overheating during extended operation, ensuring consistent performance and longevity. Enhanced ergonomic designs, such as adjustable worktables and comfortable grips, improve operator comfort and reduce fatigue during use.

The integration of digital displays and programmable settings in newer models allows for precise control and monitoring of the polishing process. Operators can store and recall specific polishing parameters, making it easier to achieve consistent results across multiple workpieces.

-

Feedback

English

English 中文简体

中文简体