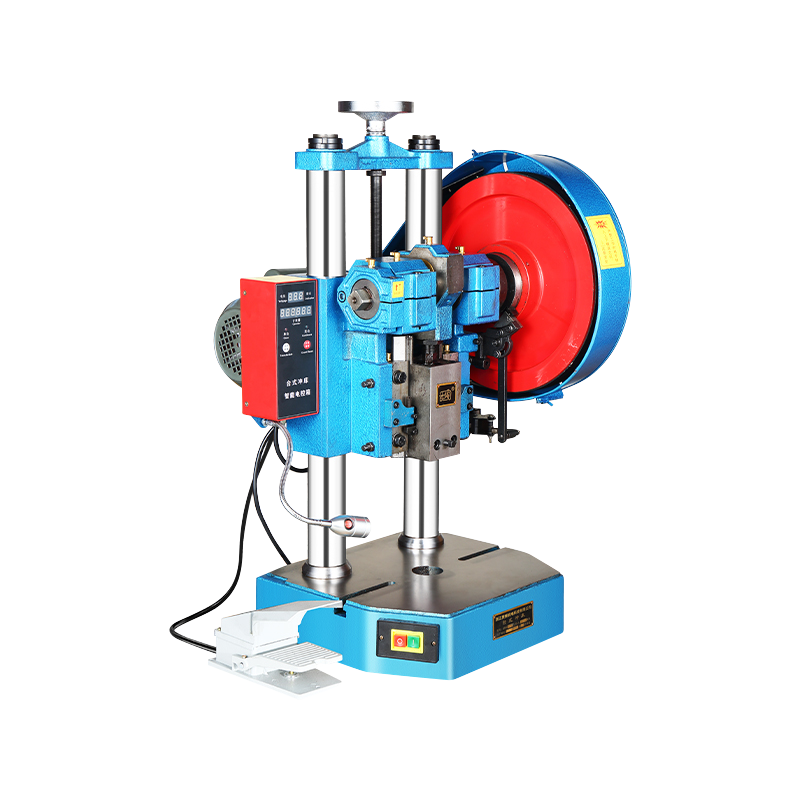

Revolutionizing Precision with the Portable Electric Semi-Automatic Tapping Machine

In the realm of precision engineering and manufacturing, the Portable Electric Semi-Automatic Tapping Machine is emerging as a key player in enhancing operational efficiency and accuracy. This innovative tool is transforming the way tapping processes are conducted across various industries by offering a blend of portability, precision, and ease of use. Here’s an in-depth look at how the Portable Electric Semi-Automatic Tapping Machine is reshaping the landscape of industrial operations.

The Portable Electric Semi-Automatic Tapping Machine is designed to streamline the tapping process, making it more efficient and less labor-intensive. Unlike traditional manual tapping tools, this machine integrates electric power with semi-automatic features to improve both the speed and accuracy of tapping operations. The portability aspect of the machine allows for flexibility in its use, enabling operators to perform tasks in various locations without the need for extensive setup.

At its core, the Portable Electric Semi-Automatic Tapping Machine uses an electric motor to drive the tapping tool, providing consistent power and reducing the physical effort required by the operator. The semi-automatic function means that while the machine handles the majority of the work, the operator is still involved in setting up and guiding the machine, ensuring precision and control.

The Portable Electric Semi-Automatic Tapping Machine is versatile and can be used across a range of applications. In the automotive industry, for instance, it is invaluable for tapping threads into engine components, brackets, and other parts where precision is crucial. Its ability to operate in various settings makes it ideal for both production lines and on-site maintenance tasks.

In the electronics sector, this machine is used to tap threaded holes in metal housings, circuit boards, and other components. The accuracy and control offered by the semi-automatic system ensure that delicate electronic parts are handled with care, preventing damage and ensuring reliable performance.

The construction and metalworking industries also benefit from the use of the Portable Electric Semi-Automatic Tapping Machine. Whether it’s for tapping holes in metal beams, fixtures, or machinery, the machine’s portability and efficiency make it a valuable tool for both on-site and workshop applications.

The economic benefits of using a Portable Electric Semi-Automatic Tapping Machine are considerable. By improving the speed and accuracy of tapping operations, the machine helps reduce labor costs and increase productivity. Its semi-automatic nature means fewer errors and rework, to cost savings and higher quality output.

Operationally, the machine offers significant improvements in efficiency and ease of use. The electric drive system eliminates the need for manual cranking or turning, reducing operator fatigue and increasing throughput. The portability aspect allows for greater flexibility in work locations, making it easier to perform tasks in confined or hard-to-reach areas.

Furthermore, the semi-automatic functionality of the machine ensures consistent results with minimal variation, which is crucial for maintaining high standards of quality and precision. This consistency helps in meeting production deadlines and maintaining the integrity of manufactured parts.

Recent advancements in the Portable Electric Semi-Automatic Tapping Machine have introduced several new features that enhance its performance and usability. Modern machines are now equipped with adjustable speed controls, allowing operators to fine-tune the tapping process according to specific requirements.

Some models come with digital displays and programmable settings, enabling users to store and recall various tapping parameters. This feature adds convenience and precision, especially when working with different materials or sizes of threads.

Improved ergonomics and safety features are also part of the latest developments. Many machines now include ergonomic handles, vibration-reducing designs, and automatic shut-off mechanisms to ensure operator comfort and safety during use.

The market for Portable Electric Semi-Automatic Tapping Machines is expanding as industries increasingly recognize the benefits of this technology. The drive towards greater efficiency, precision, and flexibility in manufacturing processes is fueling the demand for such innovative tools.

-

Feedback

English

English 中文简体

中文简体