The Evolution of the Manual Punch Press in Modern Manufacturing

The manual punch press has been a cornerstone of manufacturing processes for many decades. Its evolution from a simple mechanical tool to a more refined, versatile machine has played a significant role in shaping modern production. While automated systems and computer-controlled machines dominate many industries today, the punch press remains a key player, especially in smaller workshops or for specific tasks that demand precision and control. This article will explore how the China manual punch press has evolved over the years, examining its historical development, modern adaptations, and continuing relevance in today's manufacturing landscape.

The concept of a manual punch press dates back to the 19th century when metalworking and sheet metal fabrication were expanding rapidly. Early versions of the punch press were much simpler machines, usually powered by hand or foot pedals. Operators would manually position the material and apply force to punch holes, shapes, or patterns into metal sheets. These machines were crucial for manufacturers dealing with relatively small production volumes and custom fabrication, offering a combination of reliability and simplicity that was hard to beat.

During this time, the manual punch press primarily served industries like construction, automotive, and shipbuilding. The ability to quickly create holes or shapes in metal sheets allowed manufacturers to produce parts for a wide variety of applications. As industries grew, the demand for more efficient and specialized tools led to innovations that expanded the capabilities of the punch press.

By the mid-20th century, the manual punch press began to evolve with the introduction of various design improvements. These machines became more robust, with improved frame construction and greater capacity to handle thicker materials. As manufacturing processes became more complex, the punch press also adapted to meet the needs of an increasingly diverse range of industries.

One of the key developments in the evolution of the Custom Benchtop Punch Press was the introduction of adjustable tooling. This allowed the operator to change punches and dies quickly, facilitating different types of punching operations. The flexibility to handle various material thicknesses and types, along with the ability to make multiple types of cuts, allowed the punch press to serve a broader set of tasks. These adaptations ensured that the manual punch press remained a versatile and relevant tool in many workshops, even as automation began to take over more standardized manufacturing tasks.

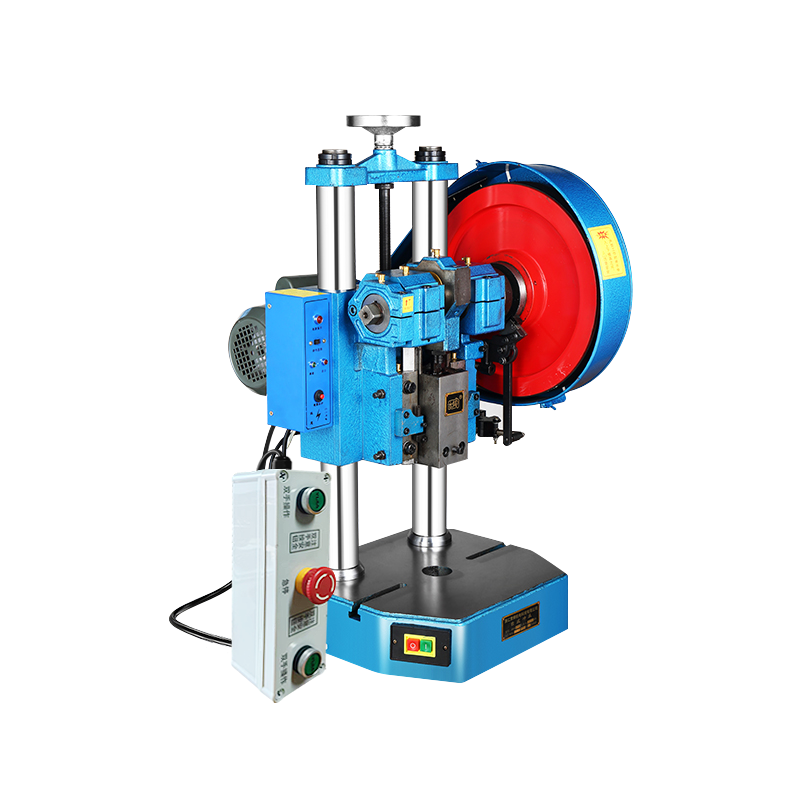

Although the manual punch press has roots in older mechanical systems, it has not been left behind as modern manufacturing techniques have advanced. Today, many punch presses are integrated with modern technologies that enhance their capabilities. For example, some manual presses are equipped with hydraulic or pneumatic systems, which reduce the amount of physical effort required by the operator while providing consistent force throughout the punching process. These systems allow for greater control and precision without sacrificing the operator’s ability to manipulate the machine.

Additionally, advancements in ergonomics have made modern manual punch presses easier and more comfortable to operate. In the past, operators had to use significant manual force to engage the press, which could be physically taxing, especially during extended use. Today, modern punch presses often feature features such as foot pedals, adjustable heights, and reduced force requirements, making them more accessible and user-friendly for operators.

While automation and digital technology continue to shape modern manufacturing, the Small Punch Press Supplier remains a relevant tool. As industry trends focus on customized and flexible production methods, the demand for versatile, user-controlled machines like the punch press is unlikely to diminish. Its adaptability, simplicity, and relatively low maintenance needs continue to make it a viable option for many businesses.

The manual punch press has undergone significant changes over the years, evolving from a simple, hand-powered tool to a versatile and efficient machine that plays an essential role in modern manufacturing. While automation has revolutionized many aspects of production, the punch press continues to be a valuable asset in workshops requiring flexibility, control, and cost-efficiency. As industries continue to adapt to changing production needs, the manual punch press will undoubtedly remain an important tool for manufacturers, offering both tradition and innovation in a single, reliable machine.

-

Feedback

English

English 中文简体

中文简体